Hyb emotional electronics brand strenghtening in China market

This operation is co-financed by European regional investment fund through Ministry of Economics, Development and Technology

HYB IS A HIGH-TECH COMPANY

We have four decades of internationally recognized experience in the research and development of thick-film hybrid circuits, pressure sensors and electronics for various applications in medicine, industrial equipment and vehicles.

We provide a full range of services covering the entire process from development to batch production in order to create custom-made products based on anticipating the needs of our customers, our experience in selling our own products and development and manufacturing for known customers.

WE CREATE MARKET OPPORTUNITIES

WE CREATE MARKET OPPORTUNITIES

We search for new creative ways to design a marketing approach adapted to the customer and the market. We build a holistic relationship with our clients, from development ideas to the end of the product life-cycle.

WE DEVELOP NEW PRODUCTS

WE DEVELOP NEW PRODUCTS

Based on the establishment of market demands and in connection with the most advanced research on earth, we develop sophisticated pressure sensors and electronics and custom solutions.

WE MANUFACTURE PRODUCTS WITH UNIQUE QUALITIES

WE MANUFACTURE PRODUCTS WITH UNIQUE QUALITIES

We produce both custom-designed products manufactured in small batches for individual customers and large-batch products – our specific knowledge and skill is built into every product.

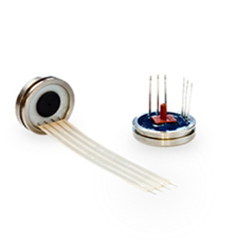

Hybysens®

Hyb’s hybysens® brand comprises components for equipment and machines. The hybysens® product group includes pressure, temperature and force sensors used in various applications, from medical devices (dialysis machines, respirators) to automated production lines, from household appliances to cars.

RESEARCH AND DEVELOPMENT

We constantly use our initial market advantage against comparable companies in the region and set ourselves ambitious global objectives on the basis of highly developed standards. Our watchword is the direct utility of our products, unique or competitive in the global environment.

Hyb development activities:

- development of medical sensors and electronics

- development of low-pressure sensors based on thick-film hybrid circuit and silicon die for various applications

- development of electronic circuits, sensors and electronics for custom applications and for known customers

- development of ceramic sensors based on LTCC technology

- research and development of new materials and technologies for micro electro-mechanical systems (MEMS)

- product development using wireless technologies

TECHNOLOGY

At Hyb we completely master all processes required for the production of pressure, temperature and force sensors, electronics and hybrid circuits. Using specific methods and approaches developed specially by Hyb, we can custom design fast and advanced solutions which are up to date with the latest guidelines, materials and design.

Hyb technological capacities:

- Production of thick-film hybrid circuits on substrates such as ceramics, Al2O3, Al, steel..

- Production of LTCC-technology based pressure sensors and other MEMS.

- Passive laser trimming of resistors. Active laser trimming of circuits.

- Attaching and wire bonding silicon dies.

- Pick-and-place of SMD components

- Encapsulation of transducers.

- Temperature compensation of transducers.

- Analogue and digital calibration.

- Spot welding.

- Ultrasonic welding.

- Cleaning and activation using low-pressure plasma.

- 100% functional control.

- Manufactured in clean rooms.